Piezo vs. Magnetic Buzzers: Which to Choose?

In today's rapidly evolving world of electronics, choosing the right components for your devices is crucial to ensure optimal functionality and user experience. Among these components, buzzers play a significant role in providing audible alerts, notifications, and alarms. When it comes to buzzers, there are two prominent options: Piezo Buzzers and Magnetic Buzzers. In this comprehensive guide, we'll delve into the intricate details of both types to help you make an informed decision for your specific application.

What are Piezo Buzzers?

Piezo buzzers are products that can produce audio signals. They are frequently incorporated into products like consumer electronics and household appliances to provide auditory cues to the end user. If you’ve ever heard the shrill chirp of a home security alarm, you have likely encountered a piezo buzzer. They can be produced at various frequencies and audio output levels.

Piezo buzzers are named for the piezoelectric materials that comprise them, which refers to their unique ability to convert energy between mechanical and electric forces. We’ll explore a bit more below how piezo buzzers are structured and how they work.

If you’re interested in learning more about piezo buzzers, check out our full article on the topic here!

Piezo Buzzer Structure

.jpg)

(Source: ISL Products)

Piezo buzzers are built and rely on the innate piezoelectric qualities of their materials to work. They consist of the following components:

- Piezoceramic material: At the center of the piezo buzzer is a piezoceramic disk that will convert electric current into sound-producing mechanical movement.

-

Metal plate: The piezoceramic disk is affixed to a metal plate for structure.

-

Electrodes: The piezoceramic disk is sandwiched between two silver electrodes, which form a circuit that sends electric current into the piezoceramic disk.

-

Plastic housing: The buzzer mechanism is generally encased in plastic housing for protection.

-

Drive circuit: The buzzer may or may not have its own drive circuit contained on the plastic housing. This drive circuit regulates the voltage inputs to the buzzer electrodes.

How Piezo Buzzers Work

Now that we know how piezo buzzers are structured, we can understand how they work. The piezoelectric process refers to the process by which some materials (such as ceramics, bone, and certain crystals) will produce an electric current when placed under physical stress.

Piezo buzzers harness the ‘reverse piezoelectric effect.’ An electric current is sent through the piezoceramic disk, causing it to vibrate rapidly and produce sound at a specific frequency.

Piezo buzzers are not the only option for buzzers, and we will explore magnetic buzzers in more detail below.

Piezo Buzzer Feedback

Some piezo buzzers have a built-in feedback feature, making their driving circuits more straightforward. This feedback line is achieved by splitting the piezo element into two different parts. When the primary piezo element moves, it presses the feedback section, generating a voltage on the feedback line.

An easy way to use this feature is by connecting the feedback line to the base of a transistor. When the piezo element vibrates, the feedback signal follows suit, causing the transistor to either block or allow current to flow alternately.

What are Magnetic Buzzers?

Magnetic buzzers are electromechanical products that, like piezo buzzers, can be used to create audio tones. They differ from piezo buzzers in their components and processes for converting electricity into sound. Magnetic buzzers are considered a more traditional choice than piezo buzzers because they rely on electromagnetic fields to function.

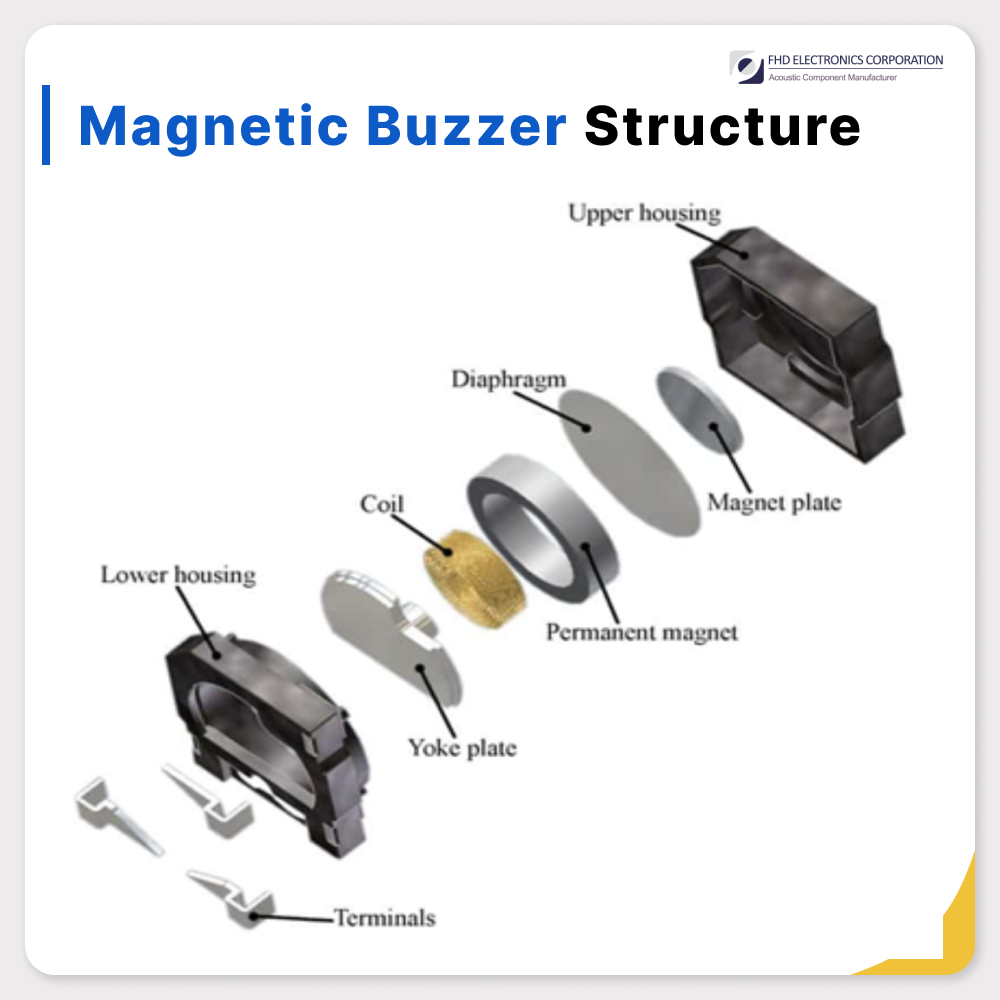

Magnetic Buzzer Structure

(Source: ISL Products)

Magnetic buzzers are built differently from piezo buzzers and have several distinct components, including:

- Ferromagnetic disk: A flexible magnetic disk at the center of magnetic buzzer assemblies.

- Coil: A wire coil located adjacent to the ferromagnetic disk, conducting electricity and producing an electric field.

- Circuit: The circuit connects to the ends of the wire coil, driving the electric current required to produce the electromagnetic field.

- Plastic housing: The entire magnetic buzzer assembly is encased in plastic housing to protect the components.

The flexibility of the ferromagnetic disk in a magnetic buzzer allows it to vibrate and produce sound, typically at a minute scale. Housed in a plastic casing, this assembly easily integrates into larger products like alarms, telephones, or children's toys.

How Magnetic Buzzers Work

An electric current is run through the wire coil at the core of a magnetic buzzer, creating an electromagnetic field. When the electric current is active, the ferromagnetic disk is attracted to it. When the electric current is stopped, the ferromagnetic disk returns to its unstressed position. By rapidly alternating between off and on, the electromagnetic field can create a rapid vibration of the ferromagnetic disk. This vibration agitates the air and creates sound waves.

Now that we’ve briefly explained the components, structure, and noise-making mechanism of piezo and magnetic buzzers, we will dig a bit deeper into what differentiates these two products below.

Variants of Buzzers

While there are five types of different buzzers, piezo and magnetic buzzers are the most common ones available on the market. Apart from piezo and magnetic buzzers, there are some variants of buzzers: electromagnetic, mechanical, and electromechanical.

Electromagnetic Buzzers

An electromagnetic buzzer comprises essential components like a magnet, solenoid coil, vibration diaphragm, oscillator, and housing. Its operation is similar to a magnetic buzzer, producing sound using magnetism at a 2 kHz frequency.

Mechanical Buzzers

Mechanical buzzers are closely related to electromagnetic buzzers, both sharing similar components. However, mechanical buzzers have vibrating parts on the outer casing. They use a magnet to create a lower-pitched buzzing sound but require more power. Matching the wire colors from the battery pack is necessary when using this type of buzzer.

Electromechanical Buzzers

Electromechanical buzzers are constructed with an electromagnet and a bare metal disc. They operate similarly to magnetic and electromagnetic buzzers, generating sound through disc movement and magnetism.

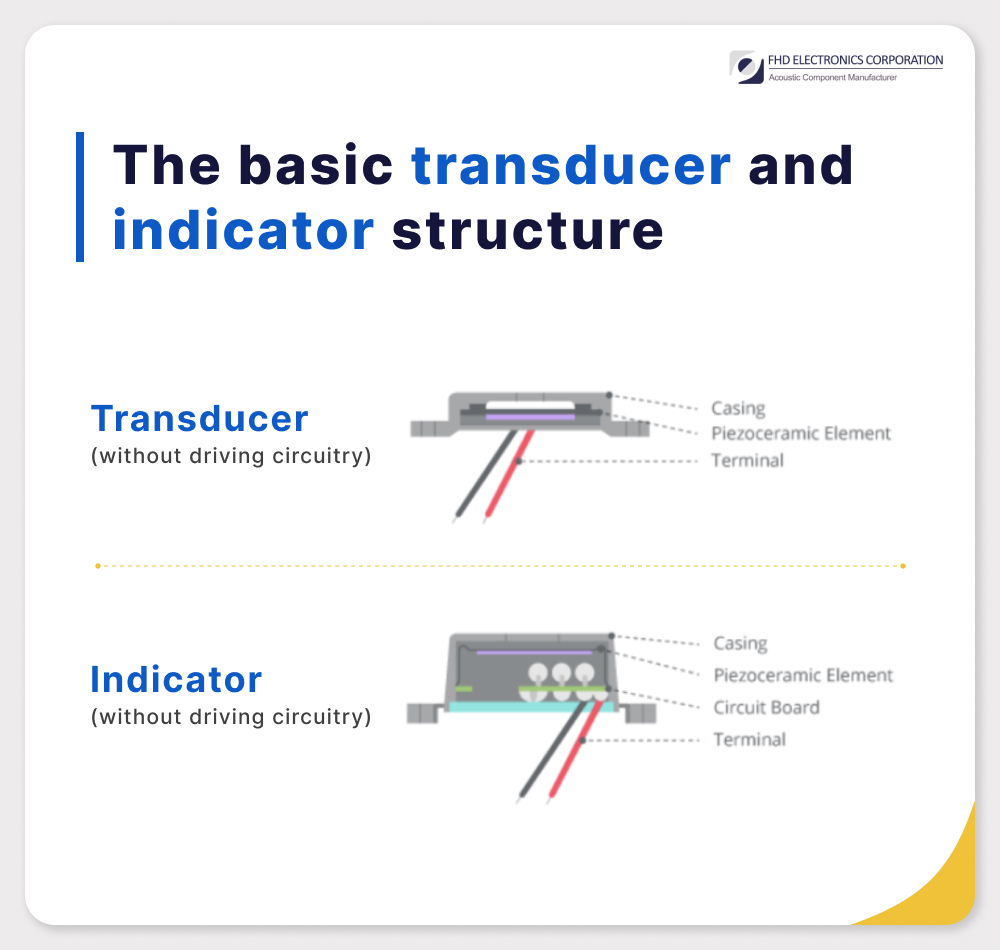

Transducer & Indicator

When incorporated into circuits in larger electronic devices, buzzers can fill multiple functions based on their drive model design. Buzzers can be either transducers or indicators. Here’s a brief explanation of the differences between these two drive models:

(Source: CUI Devices)

Buzzer Transducers

Transducer is also called external drive model buzzers. Transducer buzzers do not have their own built-in driver circuit. They must be designed into your wider system so that they can be driven by an external circuit, which can add complexity to the overall design of your product. However, this external drive model increases flexibility by customizing the buzzer's frequency or enabling multiple frequencies.

Buzzer transducers can modulate frequency thanks to their more complex external drive models. As such, they are common choices for more complex buzzer application use cases.

Magnetic and piezo transducer buzzers can be used to create more complex sounds, depending on the design of the external drive circuit. These are common choices for high-end household electronics like rice cookers and washing machines. If your appliance plays a catchy jingle when its operating cycle is complete, you likely have a buzzer transducer to thank for it.

Buzzer Indicators

An indicator is also called a self-drive model buzzer. Indicator buzzers have their own internal drive circuit. This makes it simple to integrate into wider electronic systems without design changes. However, they have a fixed frequency because a factory-set drive circuit drives them.

Buzzer indicators can only produce the fixed frequency that they are factory-set for. As such, they are a common choice for simple applications that require only a single tone. Buzzer indicators come in both piezo buzzer and magnetic buzzer formats.

Magnetic indicator buzzers have many potential uses. Because of their relative affordability and simplicity, they are a top choice for incorporating into simple consumer electronics and household electronics. They can provide helpful user feedback tones such as the beep from a button click on a home appliance.

Piezo indicator buzzers are louder than their magnetic counterparts and are a common choice for household electronic devices that make very noticeable and piercing noises, such as fire alarms and microwave timers.

Buzzer Tone

Here, we will show you some examples of the sounds that can be created by buzzers.

Warning Signal

- Continuous: Can be produced by both indicator and transducer.

Indicator Vdc: Continuously on

Transducer excitation waveform: Fixed frequency continuously

- Slow or Fast Pulse: Can be produced by both indicator and transducer.

Indicator Vdc: Switched on and off

Transducer excitation waveform: Pulsed fixed frequency

- High or Low Tone: Produced only by a transducer and associated support circuitry due to several signal frequencies.

Siren (Alarm)

Transducer excitation waveform: Ramping of frequency from low to high periodically. For example, alarm.

Chime

Transducer excitation waveform: Single cycle between high and low frequencies slowly. For example, the doorbell.

Applications Circuit for Transducers and Indicators

Piezo or Magnetic Indicator

An indicator is the simplest of the two functions, requiring only a direct current (dc) voltage to operate and produce sound whenever the voltage is present. As the name has suggested, they alert users when a specific event occurs. That’s why they only produce a single sound output in a fixed format, making their application very user-friendly for designers. For example, a sound like an alarm can be produced by simply switching the input voltage on and off.

Manufacturers integrated all the required electronic circuits to simplify the design process, transforming the basic magnetic or piezo buzzer formats into indicators, including the waveform generator, into the package so that a simple control voltage can make the buzz sounds.

To create more sounds, a transducer will be a more suitable choice as it allows designers to set the output's frequency, tone, attack, persistence, and decay. The complexity of the controlling circuit determines the complexity of the produced sound.

Magnetic Transducer

Piezo Transducer

A piezo transducer can be activated using a circuit like a magnetic transducer. Since piezo transducers have low inductance, sometimes placing a diode across the transducer is unnecessary. Still, a resistor is needed to reset the voltage when the switch is turned, although it is not common for a resistor to be used to operate piezo transducers. Other circuits are typically utilized to make the sound level bigger from a piezo transducer by increasing the peak-to-peak voltage applied.

Buzzer Key Specifications

Operating Voltage

Both piezo buzzers and magnetic buzzers can operate at various voltages, depending on the specific model. Generally, piezo buzzers are voltage-driven devices, with a wide operating voltage range from about 3V to 220V and typically consuming less than 20mA. Magnetic buzzers primarily rely on electric current and often require more current. Some models may start as low as 10mA, while others may exceed 20mA, depending on design and application choices. They can operate at lower voltages, typically ranging from about 1.5V to not exceeding 12V. It's crucial to select a buzzer type and model that aligns with your application's electrical specifications.

Resonant Frequency

Resonant frequency refers to the specific frequency at which a material tends to vibrate. For both piezo and magnetic buzzers, sound is generated through the vibration of a resonant element. Piezo buzzers, with piezoceramic disks as their resonant element, tend to have higher resonant frequencies, typically ranging from 2 to 6 kHz. In contrast, magnetic buzzers with ferromagnetic disks have lower resonant frequencies, typically falling in the 1 to 3 kHz range. Oscillation near the natural frequency enhances energy efficiency as it requires less electrical input to generate movement and sound.

Frequency Response

Frequency response measures how well a buzzer can produce different sound frequencies. Piezo buzzers tend to provide more consistent sound across different pitches, while magnetic buzzers can be somewhat less predictable. Consequently, piezo buzzers can cover a wider range of pitches compared to magnetic buzzers.

Sound Pressure Level(SPL)

Sound pressure level (SPL) quantifies the impact of sound waves produced by the buzzer on nearby air pressure. It is calculated as the deviation from standard atmospheric pressure and is typically measured from 10cm away in industry-standard tests. SPL is proportional to the input voltage and is usually expressed in Pascals (Pa) or decibels (dB). Piezo buzzers generally have higher SPL values (ranging from 85 to 120 dB) than magnetic buzzers (ranging from 70 to 95 dB). Buzzers with lower SPL values may require more powerful amplifiers to achieve higher volume levels.

Impedance

Electrical impedance relates to the relationship between applied voltage and resulting current, and this relationship varies with frequency.

Mounting Styles

Buzzers come in various mounting configurations to suit different application needs, including panel mount, screw terminals, spring contact, surface mount, through-hole, wire leads, and more.

How to Choose the Right Buzzers for Applications

When selecting a buzzer, consider your application's electrical and physical parameters. Factors like operating voltage, current consumption, resonant frequency, frequency response, sound pressure level, impedance, mounting style, and size play pivotal roles in choosing between a piezo buzzer and a magnetic buzzer.

The comparison table below highlights the key technical specifications that guide the selection of the right buzzer based on your application's requirements.

| Piezo Buzzer | Magnetic Buzzer | |

| Method of Operation | Piezoelectric Effect | Electromagnetic Effect |

| Operating Voltage | 3~ 250V | 1.5 ~ 12 V |

| Resonant Frequency | 2 ~ 6 kHz | 1~ 3 kHz |

| Frequency Response | Larger | Smaller |

| Sound Pressure Level(SPL) | 85 ~ 120 dB | 70 ~95dB |

| Current Consumption (I) | <10mA | 20-60mA |

| Size | 12mm ~ 50mm | 7mm ~ 25mm |

At FHD Electronic Corporation, we manufacture and supply buzzers tailored to your precise specifications for any application. If you're ready to initiate a project, kindly submit your requirements, and our team will promptly assist you.

Finding the Best Piezo and Magnetic Buzzer Manufacturer

FHD Electronic Corporation is a leading electric buzzer manufacturer known for exceptional customer service and unwavering commitment to quality. Additionally, we offer warehousing and repackaging services, making us a one-stop solution for your buzzer needs and a crucial partner in the end-to-end buzzer manufacturing and sales process.

Explore our popular piezo and magnetic buzzer products today, each designed to meet specific use case requirements. Click on the links provided in the tables below for full specifications.

|

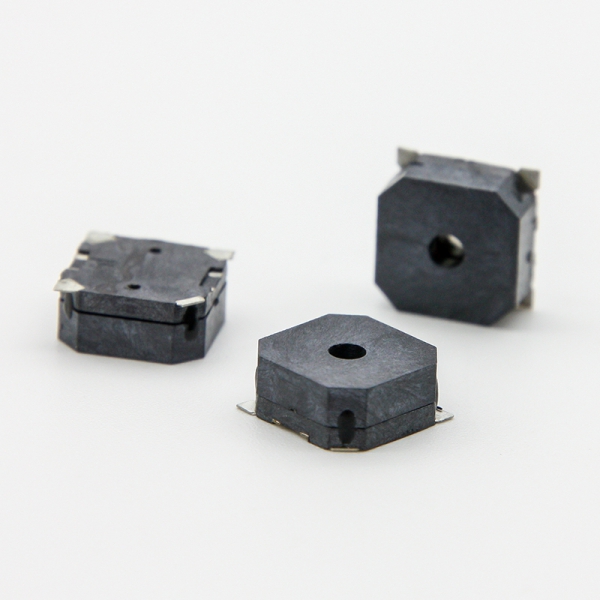

Buzzer Image |

Buzzer Name & Model Number | Type | Dimensions | Frequency | Rated Voltage | Max Current | Min SPL | Operating Temperature |

|

Magnetic Buzzer, Surface Mount, 100dB @5Vo-p, 10cm Potting Process Allowed |

Magnetic Transducer | 8.5mm x 8.5mm x 4mm | 4,000Hz | 5V | 100mA | 100dB | -20℃ to 70℃ |

|

Magnetic Buzzer, Surface Mount, 75dB @3Vo-p, 10cm BEAUTY INSTRUMENT, SHAVER, APPLIANCES No. T050520-M4000E-S |

Magnetic Transducer | 5.2mm x 5.2mm x 2mm | 4,000Hz | 3V | 100mA | 75dB | -20℃ to 70℃ |

|

Piezo Buzzer, PCB Mount, Min. 80dB@12Vp-p, 10cm, Spring Structure, Cost Saving Design No. T12670-P4000A-J |

Piezo Transducer | 12.6mm (diameter) x 7mm (height) | 4,000 ± 500Hz | 3V | 100mA | 100dB | -20℃ to 70℃ |

|

Magnetic Buzzer, PCB Mount, 85dB @5Vo-p, 10cm No. T12095-M2400G-P |

Magnetic Transducer | 12mm (diameter) x 9.5mm (height) | 2,400Hz | 5V | 25mA | 85dB | -20℃ to 70℃ |

|

Piezo Buzzer, PCB Mount, Min. 85dB@5Vp-p, 10cm, IP67, waterproof |

Piezo Transducer | 13.8mm (diameter) x 6.8mm (height) | 4,000 ± 500Hz | 5V |

5mA | 85dB | -20℃ to 70℃ |

|

Magnetic Buzzer, Circuit build drive, PCB Mount, Min. 85dB@5VDC, 10cm No. I09650-MC2700G-P |

Piezo Indicator | 12.6mm (diameter) x 7mm (height) | 2,700 ± 300Hz | 5V | 30mA | 85dB | -20℃ to 70℃ |

|

Magnetic Buzzer, Surface Mount, 75dB @3Vo-p, 10cm BEAUTY INSTRUMENT, SHAVER, APPLIANCES |

Magnetic Transducer | 5mm x 5mm x 2.5mm | 4,000Hz | 3V | 100mA | 75dB | -20℃ to 70℃ |

|

Magnetic Buzzer, Surface Mount, 85dB @3Vo-p, 10cm No. T091027-M2700E-S |

Magnetic Transducer | 9mm x 10.5mm x 2.7mm | 2,700Hz | 3V | 90mA | 85dB | -20℃ to 70℃ |

Conclusion

In the ever-evolving world of electronics, selecting the right buzzer is essential to ensure optimal performance. Piezo and magnetic buzzers offer unique characteristics suitable for various applications. Understanding their differences and key specifications allows you to make informed decisions and choose the ideal buzzer for your specific needs. At FHD Electronic Corporation, we are committed to delivering buzzer solutions that align with your precise requirements. If you're ready to embark on a project or need further assistance, please call us at +1- 469-409-2828, email us at sales@fhdmfg.com, or complete the inquiry form today.

Contact us today if you want to discuss your buzzer requirements with us.

Related Articles Suggested For You:

Understanding MEMS Microphone Technology: 2023 Audio Revolution